Quality Assurance

Quality is not an act. It is a habit.

Superior quality is the primary concern at Sterling Brass Industries. We strictly adhere to stringent quality management systems in order to facilitate an error free production from every stage. Our entire manufacturing process is monitored by a team of well professionals having years of experience behind them. A team of trained supervisors and quality control inspectors ensures that the quality is maintained at all the stages of production.

Our target is to provide zero defects products to client which is remarkable in industry. To meet the global demand we take care at every stage right from raw material purchase to finished goods. Our quality assurance team is trained and well experienced. To achieve the maximum standard our quality control team continuously monitors the products and user requirement right from the production stage up to the final dispatch. Due to strict quality control procedures our customers are ensured that their requirements are met accurately.

Production processes are set with in-depth understanding about customer's requirement and product application which means quality is built into the processes for producing products and continual improvement measures are taken to ensure the processes work every time.

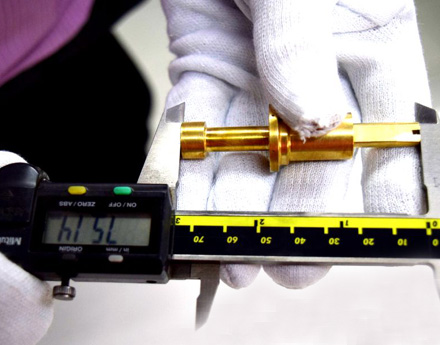

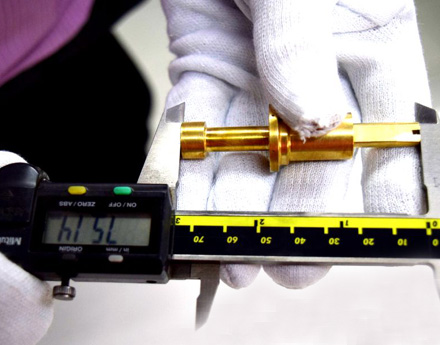

Quality Control

After product produced, it has been send to QC Department. Quality Control Supervisor will check all dimensions and measurements on the basis of various quality checking methods. If reports are under required tolerance then material will be sent to next department.

Instruments

Instruments are the heartbeats of industry, to assure good quality, Instruments are required. Company has invested a good amount behind this to have majority type of Inspection instruments including all instruments and gauges along with the profile projector and other sensitive instruments.

Quality Inspection

Company has unique Inspection facility to achieve the goal to zero defects and rejection of any products manufactured. Well experienced and regularly trained technocrat engineers, carry out the Inspection on each Individual product. Batch Inspection is not permitted in the company.

Packing & Dispatch

Packaging is the most important aspect. After Inspection, each order is directed to a particular packing location. The completeness of whole order can be checked here optionally. Than the packing list gets printed to be included into the packing and the whole order is packed and dispatched.

Quality Policy

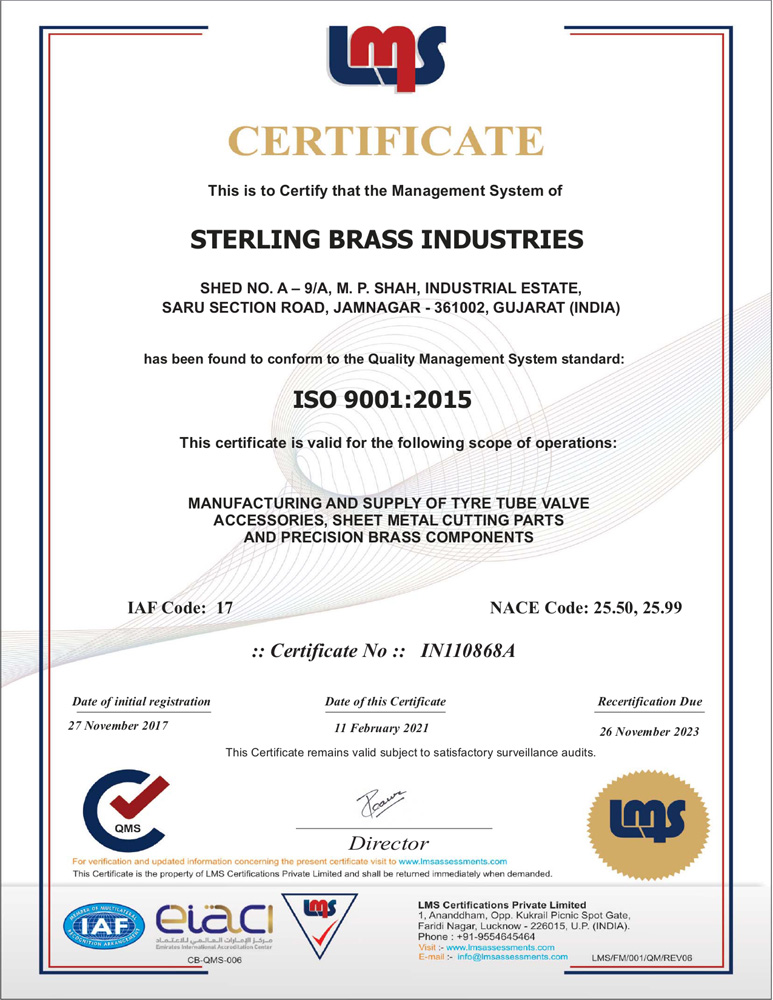

We are a team of professionals focused on manufacturing the highest quality products at a fair value that meets and exceeds our customer’s expectations. Every employee of the company is committed to the pursuit of excellence with continuous improvement of the Quality Management System.

- ISO 9001:2015 Certified Company

- Modern & Innovative Infrastructure

- Seperate R&D Department

- Experienced & Dedicated Team

- Skilled Employees

- On Time Delivery